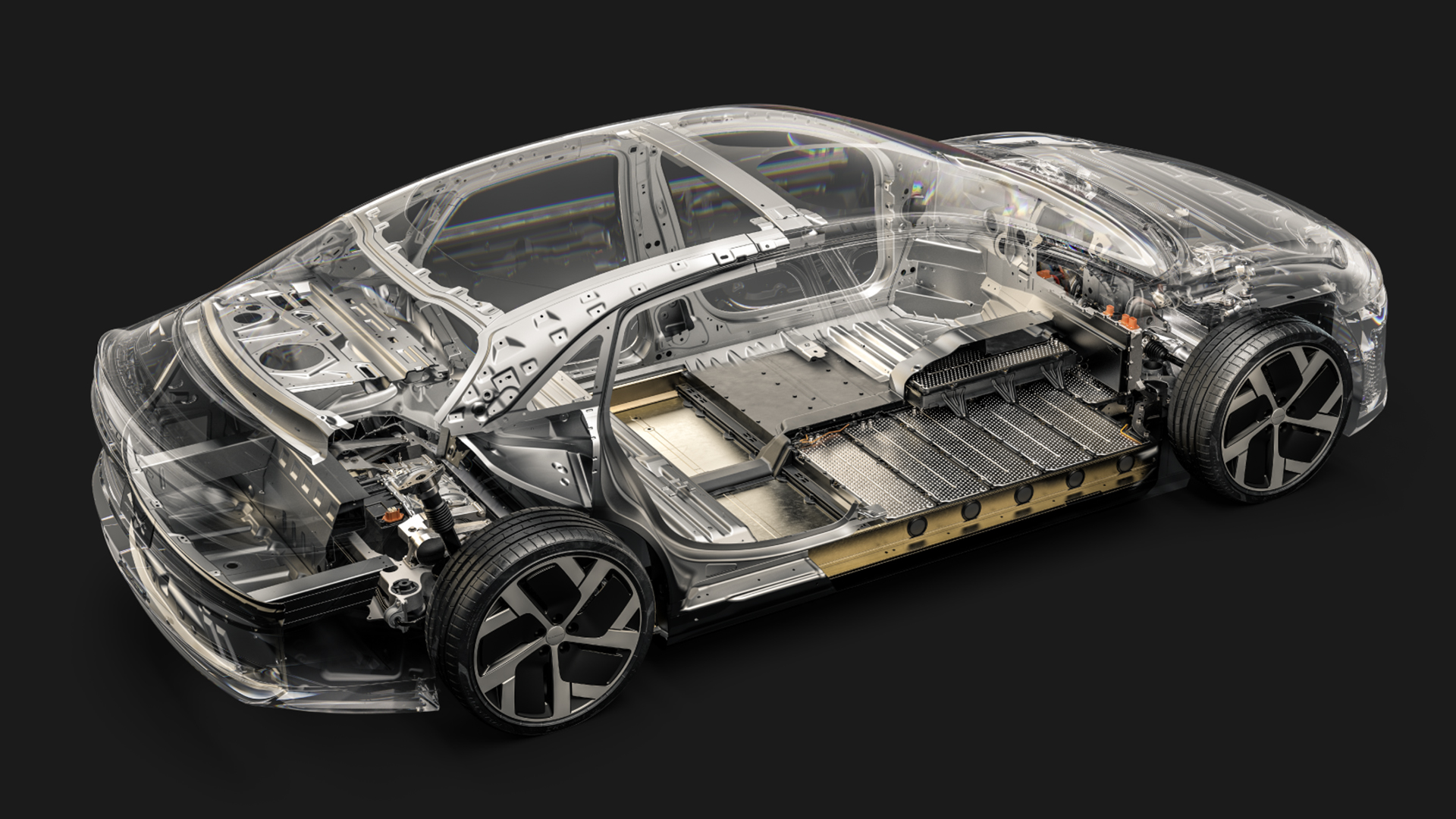

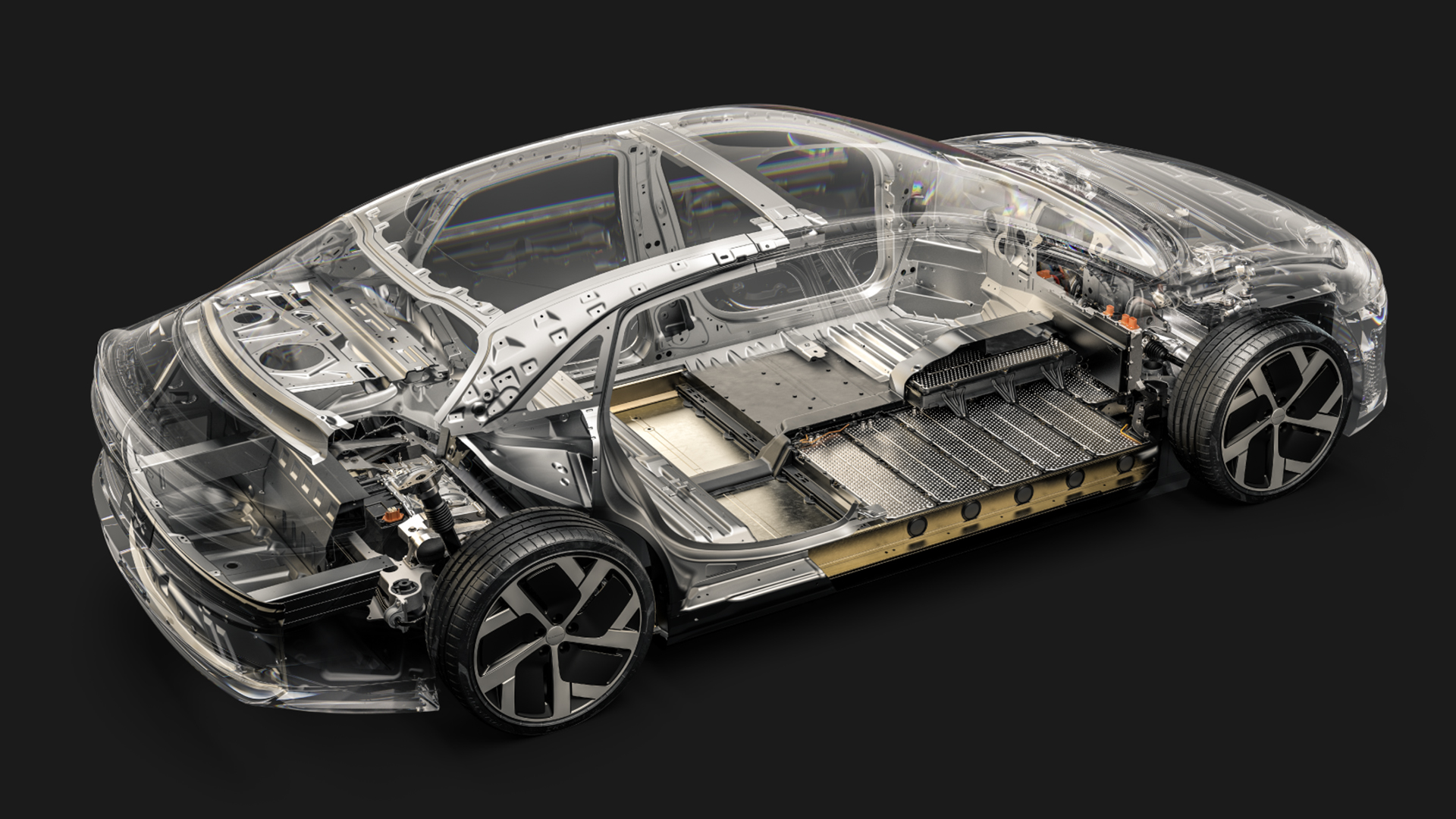

Electric vehicle batteries are the biggest lithium-ion units we mass produce, and they’re horrible.

Battery electric evangelists Tesla are making dire predictions about running out of rare-earth minerals to even make them. Right-thinking people are raising extremely legitimate concerns are being raised about the appalling conditions a lot of the elements necessary to make lithium-ion batteries are mined and produced in. And making batteries is a serious carbon problem, accounting for between 15 and 68 percent more production CO2 than a gasoline car.

Which is why Tesla co-founder J B Straubel announced this week he’s building a “gigarecycling” plant to essentially do the opposite of the Gigafactory. At the moment, where lithium-ion EV batteries are recycled it’s almost always in a fairly awful, mechanical digestion process that recovers less than half of the materials used, at best.

There are companies offering better solutions already, like Finnish outfit Fortum, who claim they can recover 80% of the materials used in an EV battery but one clear thing would make the entire process way more simple: build the batteries to be recycled.

That’s easier said than done, we’re still pretty early on in the phases of building EV batteries at all. But the automotive industry has done this before, when an environmental nightmare threatened to force them to stop otherwise.

Just in case you’re logging on to the internet and reading this article from some kind of utopian bubble, not the fear-encased hellscape of the 2020s, you might not feel a high-level horror about literally everything everyone’s been doing for the past two hundred years. If that’s the case, I really recommend googling “historic coastal landfill.”

It sounds so harmless, doesn’t it? Somewhere you’d go on a school field trip, maybe, to learn about historic garbage. Unfortunately, it’s actually one of the several million things that are trying to kill everything in the sea and us with them.

Quaint seaside enthusiasts England have more than 1,200 historic coastal landfill sites that they’re doing a sum total of mostly nothing about, which is really bad because there’s some horrible stuff in there.

One of the worst things is that you just used to be allowed to throw lead-acid car batteries into a sand dune and assume it’d be someone else’s problem. Ah, Boomers. It’s now a problem, obviously but the one bright spark in the situation is that it could, for once, be massively worse.

When cars first started having batteries they looked like whatever the automaker wanted them to look like. You might’ve noticed that today all 12v automotive batteries are basically the same in design terms, which makes them super easy to change, like standard AAs in a TV remote. Neat.

It also makes them super easy to recycle, which is why they’re now one of the greenest things in a vehicle at 90% recycled material usage. The plastic casing and lead can just be reused, bar major damage and the sulphuric acid electrolyte gets neutralized and replaced. That’s extremely cool and means that, depressing British seaside resorts aside, we don’t have to fill anywhere else with really toxic and bad stuff in flimsy little plastic cases.

It didn’t happen organically. The automotive industry made a choice to do it because they knew cleaning up the problem of lead-acid batteries was going to get them in monumental amounts of trouble otherwise. Since the 1970s that’s sort of been a major theme of ‘things that happen to the automotive industry,’ though and they’ve got pretty good at ignoring them.

Right now, if we don’t convert to battery electric vehicles we might not have cars. Which is a really terrible forecast for an industry dedicated to making them. And since research into vehicle batteries has been an on-off (mostly off) project since Moritz von Jacobi made a load of Tsar Nicholas II’s friends puke from noxious fumes on an electric boat in 1839, they’re where auto-makers are having to seriously play R&D catch-up.

There’s some hope. Landfill recycling is proving worthwhile in its trial programs, but the problem comes from things like smartphones and computers and TVs and yeah, batteries that end up in there without a plan of how to recover the elements from them. Remember that scene from Bladerunner 2049 where there’s a factory full of children recovering metal from a scrapheap? It’s more likely than you think, if we want to get the elements back out of millions of old iPhone 2s.

But we don’t have time to spend a few decades shoveling lithium-ion into the sand banks at sad, windswept holiday resorts mostly used to shoot meaningful indie films about the naiveté of youth, this time. And for the car world, EV batteries are big enough that a lot of other industries can stick their heads in the carbon swirl if automotive doesn’t lead on prioritizing recyclable design.

Automakers worked together once to sort this out. And although it’s right to be cynical about any of Tesla or Tesla-adjacent company’s battery announcements, Straubel’s recycling company teaming up with both Panasonic and Amazon to try and work towards better recovery and recycling is a very good start.

OEMs will be reluctant to share IP or common design but if we’re going to avoid a battery disaster, the 12v example is a rare moment where we actually averted the inevitable.