In a press release Friday, BMW Design Department announced in collaboration with the MIT Self-Assembly Laboratory that the two have developed 3D-printable inflatables, with air sealed inside. BMW’s head of brand vision Martina Starke sees the material as building blocks for future interior designs for cars.

“The outcome of this collaboration manifests that a new material future is imminent,” stated Starke in the press release. “There is no need to lock the car of the future into any particular shape. Interiors could even take on malleable, modular uses.”

As returns from refining traditional engineering, design, and manufacturing practices diminish, 3D printing and other additive manufacturing technologies are gaining traction with automakers, who seek high-tech solutions to the ever-increasing complexity of modern vehicles.

The partnership between BMW and MIT began two years ago. BMW sought to develop inflatable components that could be manufactured in any shape or size, unconstrained by the limitations of traditional manufacturing techniques.

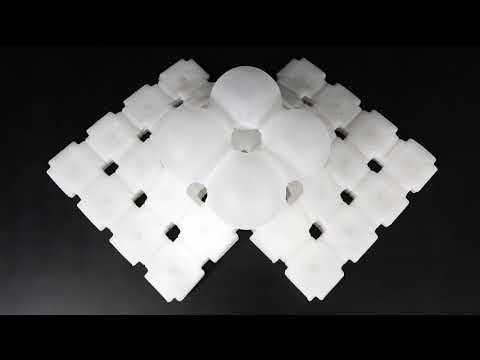

Results of two years’ work can be seen in photographs and video released by BMW, which depict a sheet of 3D-printed silicone bubbles actively changing shape as its air controls redirect pneumatic pressure between its chambers.

“We then brought together a number of recent technologies such as Rapid Liquid Printing and techniques from soft robotics to achieve this adaptive material structure,” described the lab’s founder, Skylar Tibbits.

“In the past, scenarios like these have often required errorprone and complex electromechanical devices or complex moulding/tooling to produce inflatables. Now we’re able to print complex inflatable structures with custom actuation and tuneable stiffness,” said Tibbits.

General Motors uses cloud computing and 3D printing to step up its component design, which could result in lighter, yet still stronger metal parts, without venturing into the costly realm of composite materials. On the flip side, 3D printing also allows cost-effective, on-demand production of parts in low demand, such as those for maintaining classic cars, as Porsche does.