We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Automakers may not be 3-D-printing parts for new cars just yet, but Daimler thinks the technology could be pretty handy for spares. The carmaker began 3-D printing plastic spare parts for Mercedes-Benz trucks last year, and now, it’s moved on to its first 3-D-printed metal replacement part.

It’s a thermostat cover made from a blend of aluminum and silicon, used on older models of Mercedes commercial trucks and Unimog utility vehicles. Daimler believes 3-D printing could be a more cost-effective way of keeping spares available for customers.

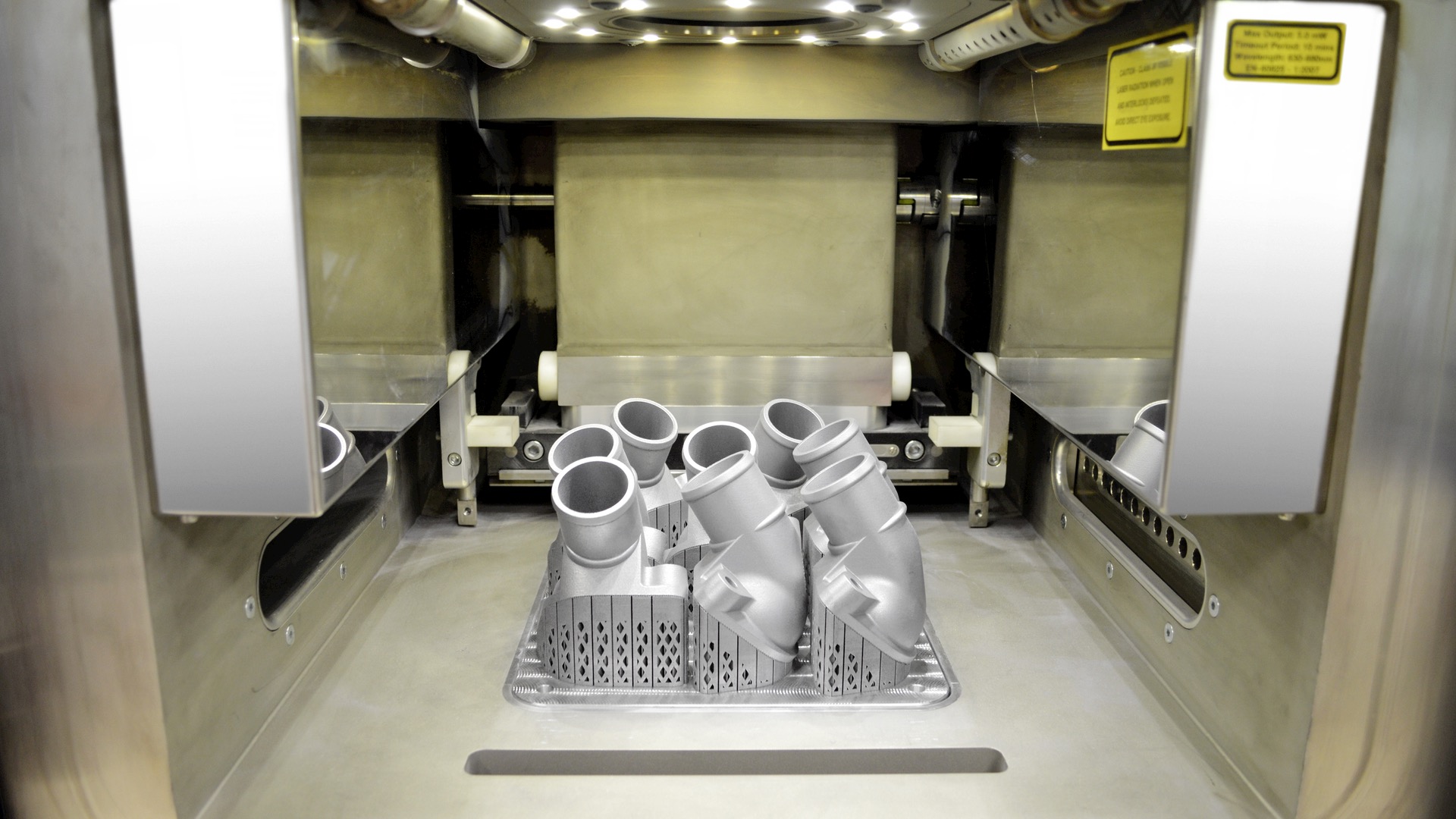

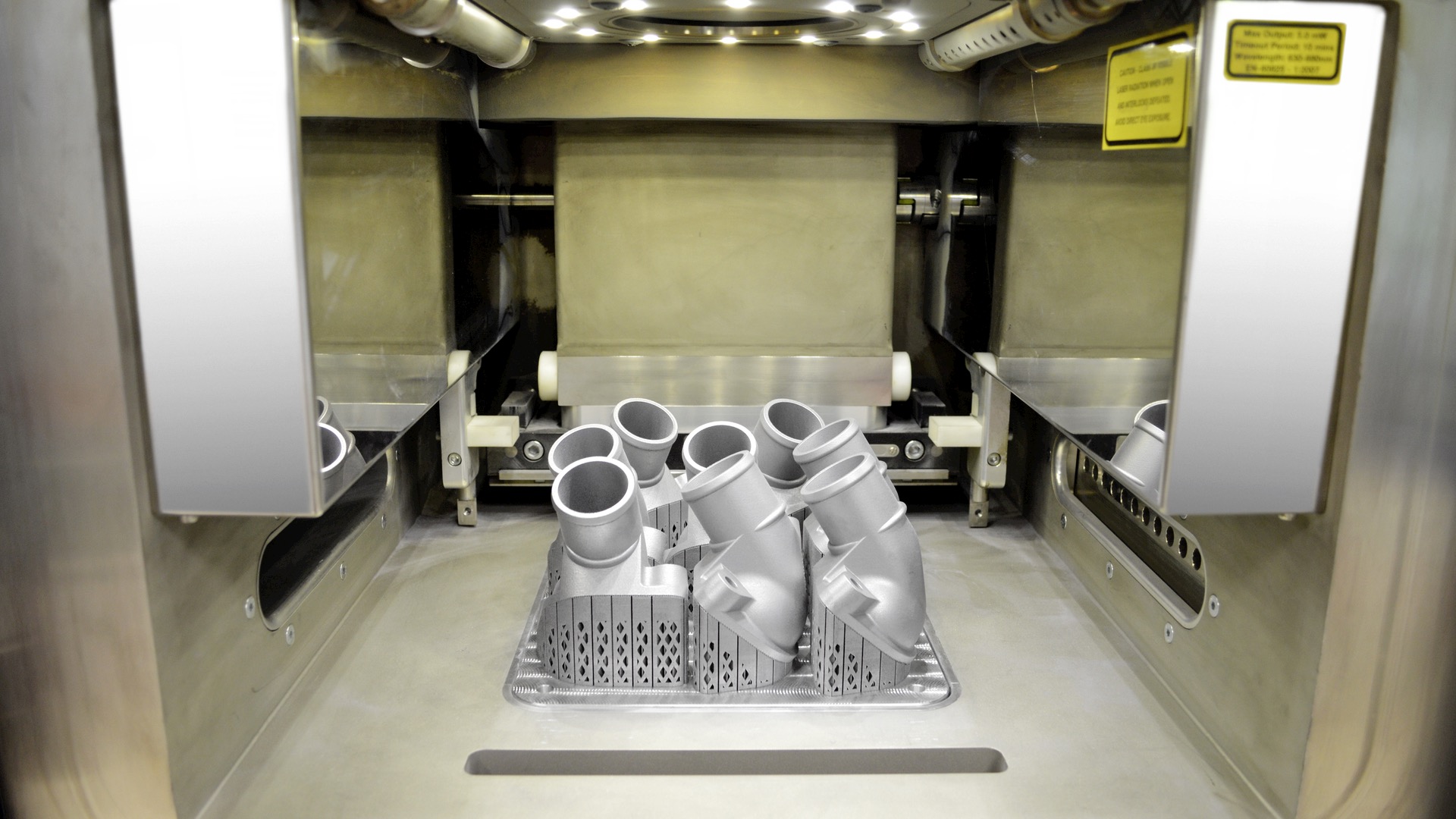

As with other forms of 3-D printing, the thermostat covers are made by adding layers of material until the proper shape is achieved—only instead of the plastic pellets used in most other 3D-printed products, the material used here is an aluminum-silicon powder, which is melted by lasers. New layers of powder are applied on top until the part is completed.

Daimler claims the 3-D-printed parts are just as strong as the originals, but much easier and cheaper to produce. Since the vehicles using these parts went out of production 15 years ago, there is relatively little demand for the replacement pieces. Daimler says it thinks 3-D printing will make it easier to meet whatever demand does exist, without the cost of warehousing stockpiles of parts or tooling up for a production run using conventional processes.

For now, small-batch production runs like this seem to be the best use of 3-D printing. While Local Motors famously 3-D-printed the entire body for its Strati electric car, it may take a while for traditional automakers to embrace 3-D printing on such a large scale. But with so many changes occurring so quickly in the auto industry these days…you never know.