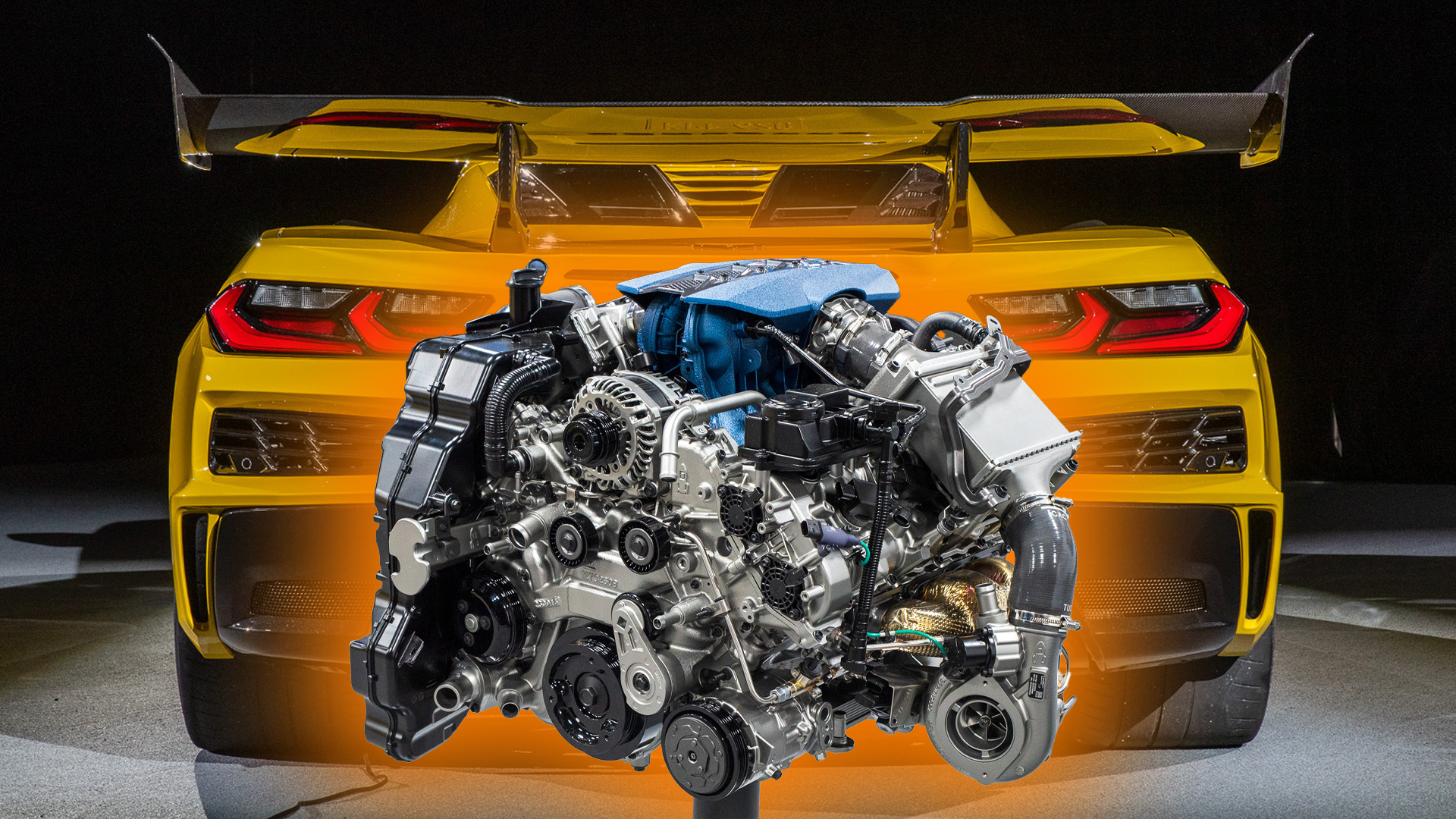

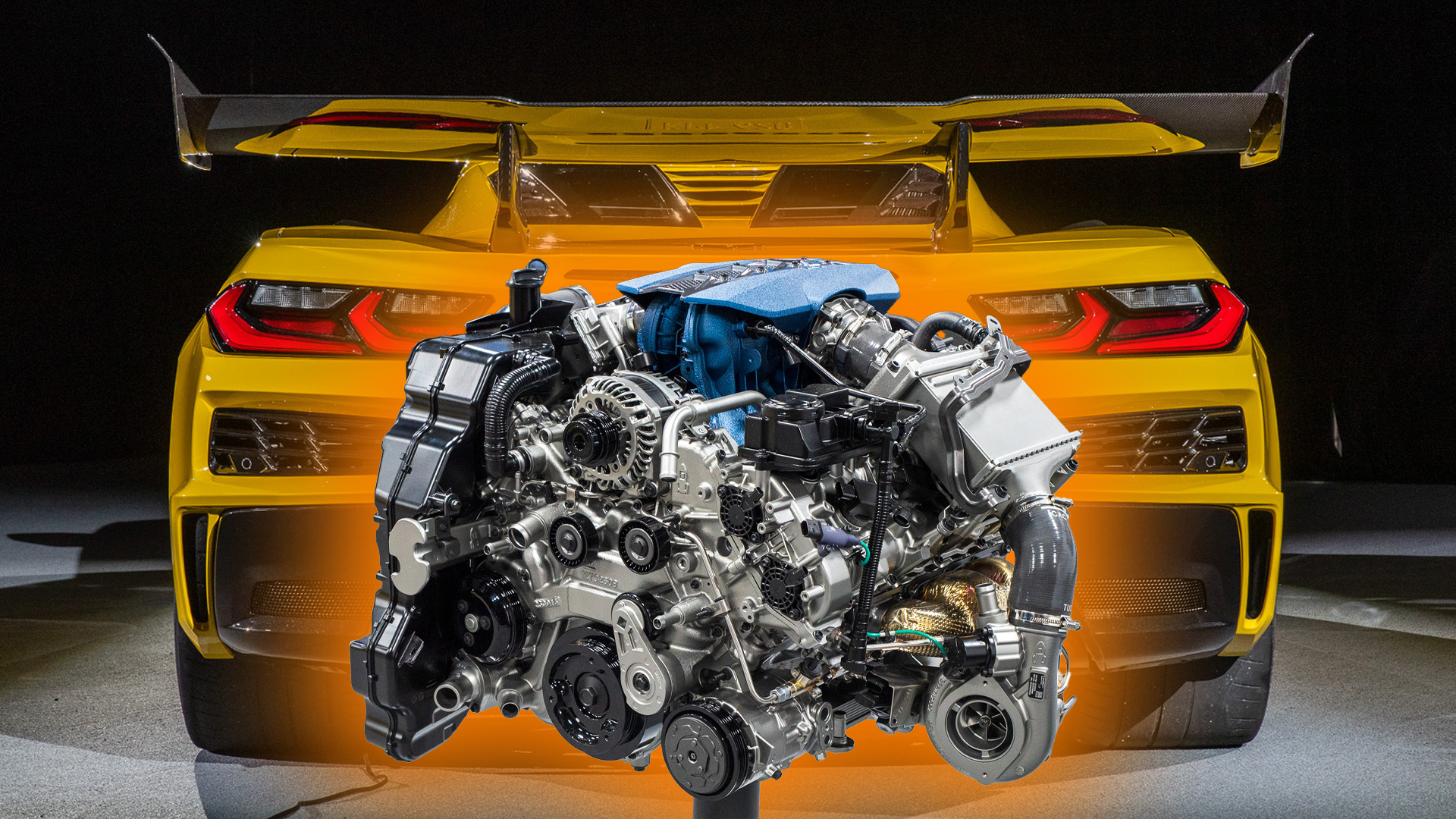

In case you haven’t heard, the 2025 Chevy Corvette ZR1 is here and ready to throw down with 1,064 horsepower. That’s a whole heckuva lot, and it makes all of it without any help from electrification. Instead, there are two 76-millimeter turbos strapped to a rippin’ 5.5-liter, flat-plane crank V8. And while forced induction is nothing new to Corvette, turbos are. There’s a reason for that.

I talked about this with Dustin Gardner, assistant chief engineer for the LT7, while at a media sneak peek of the car in June. (Keeping quiet about it for a full month was hard, believe me.) During our conversation, Gardner mentioned that all roads led to the ZR1 getting turbos, and the C8 platform is what finally unlocked it. “These [LT6 and LT7] engines—the Gemini twins, as we call them—I’ve been working on them for over seven years now. It’s always been the plan,” Gardner told me. “The C8 architecture was there to enable this, right? The LT6, just being tall, could never go in the front and the LT7, being so wide… and with this much power and torque, you need a chassis like this to be able to use it. You put 1,000 hp in a front-engined car and you’re not going to be able to use it.”

With a turbo strapped to each side of the LT7, it could never fit between wheels that turn. The engine itself is inherently wide with its dual-overhead cams and flat-plane crankshaft, which meant packaging was still a mighty obstacle for the engineering team. Gardner said that was his favorite thing to tell people about the project—“other than the horsepower,” he clarified.

“The biggest thing to me is the integration of the turbochargers—them actually being as close to the engine as they are,” Gardner elaborated. “There were a lot of challenges to get the turbine housings integrated with the manifold mounted to the engine. The way that works together to make this power—there are really exotic materials in there. We can see almost 1,900 degrees Fahrenheit in that turbine housing at peak power, so it’s huge. Doing a true ball bearing turbo, it spools fast, it’s what you hear and feel in the car.”

Speaking of temperatures and cooling, that’s been an unfortunate concern for previous boosted Corvettes. I asked Gardner about this directly, and he seems sure that they’re better able to manage that with turbos as well as the throwback split rear window.

“I’d say they’re easier because your packaging is more forgiving,” he said. “You can have your intercoolers outside your charging device; with a supercharger, you’re really constricted by the distance between your rotors and your intake, and generally, you aren’t left a lot of real estate.

“With turbos, we can mount very large, very efficient air-to-water intercoolers. From a charge cooling perspective, I would say these are easier to work with. There are added challenges that come with turbos like getting coolant and oil to and from them, but with the Gemini architecture having the scavenge pumps we do, it makes it easier on the oil side. It’s like, ‘Hey, we’ll just put a seventh scavenge stage on there that will solely be dedicated to managing oil for the turbos.”

So there ya have it. While the ZR1 has always been “a charged solution” in the modern era, as Corvette Executive Chief Engineer Tadge Juechter told me, the C6 and C7 both made do with superchargers because of their front-engined layout. Now, the C8 doesn’t have the same limitations. I’m honestly not sure this car has any limitations—other than the person behind the wheel.

Got a tip or question for the author? Contact them directly: caleb@thedrive.com