We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Turbochargers are wonderful things, taking waste energy and using it to help an engine to produce more power. The variable-geometry turbocharger is an advanced version of this technology, which brings several benefits along with an increase in complexity. Thanks to a video shot by KF Turbo on Instagram, we can take a closer look at what makes a variable geometry turbo so special.

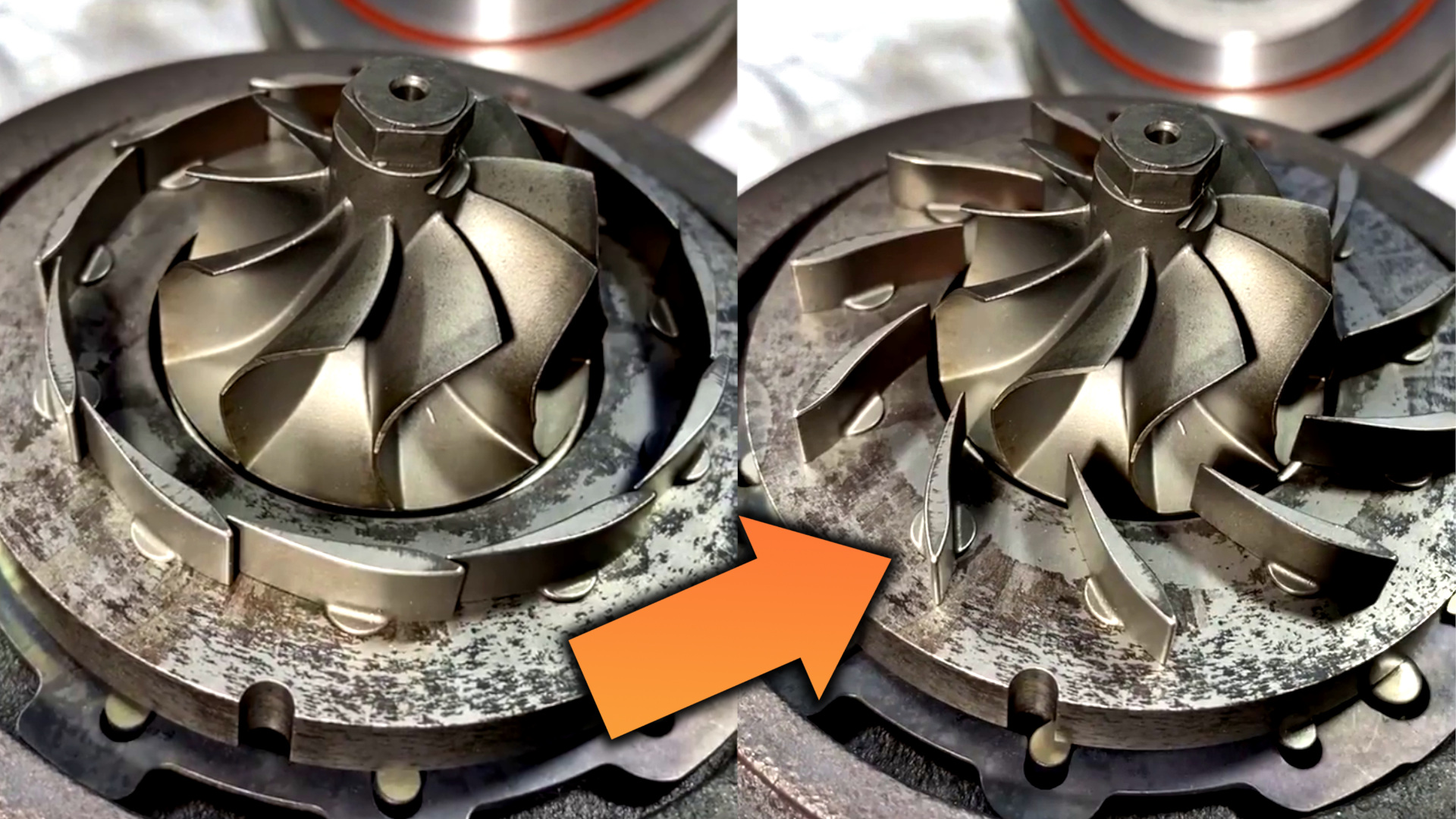

The video shows us inside a typical moving-vane variable geometry turbocharger. This consists of a set of vanes that sit around the exhaust turbine, with their angle controlled by an actuator. Other designs exist too with vanes that move up and down, for example; these are more common on heavier-duty applications like trucks or other large vehicles.

In a regular fixed-geometry turbocharger, exhaust gas is passed through the turbine to spin it up, thus turning the attached compressor which generates boost for the engine. At low engine speeds, the engine does not generate enough exhaust flow to spin the turbine up and generate meaningful boost levels. At this point, the system is said to be below the boost threshold.

Once the engine reaches a suitably high RPM to generate boost, it still takes some time to spin the turbine up to speed; this is known as turbo lag. Turbo lag and boost threshold are both higher for larger turbines, which take more energy to spin up. However, these higher-flowing turbines are capable of generating more power. It’s a trade-off, as so many things are in engineering.

The variable geometry turbocharger seeks to change this with the addition of vanes or other features that functionally alter the geometry of the turbine system. In a rotating vane turbocharger like we see here, the vanes remain largely closed at low engine speed, restricting the flow of exhaust towards the blades. This restriction increases the speed of the flow, helping the exhaust gases get the turbine up to speed faster. This bring down the boost threshold and reduces turbo lag.

However, having such a restriction would be a major penalty at higher RPM, where the engine needs to pump out more exhaust to make power. In this condition, the vanes are opened to allow as much exhaust gas to flow through the turbo as possible, avoiding a restriction that would increase backpressure and reduces power.

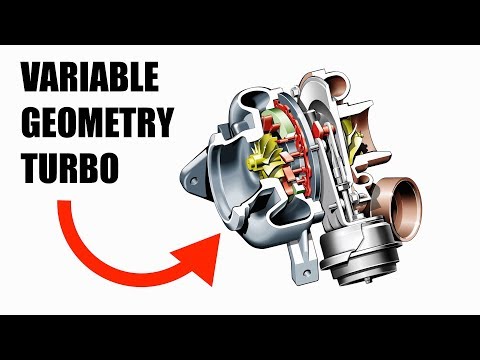

Thus, the variable geometry turbo really is the best of both worlds. A VGT can generate big power without the usual trade-off of high boost threshold and turbo lag that usually comes with fitting a large turbo. Overall efficiency is improved, too, and the vanes can even be used as an engine brake in some applications as well. The video below from Engineering Explained is a great explainer of how this technology works, with the aid of a helpful whiteboard diagram.

The trade-off here is complexity. Material choice is paramount, as the moveable vanes must deal with scorching hot exhaust temperatures without seizing in place due to thermal expansion. An actuator must be fitted to control the vanes, and the vanes must be controlled, typically by the engine control unit, to ensure the vane position is ideal for the engine’s operating condition.

Such complexity has traditionally kept variable geometry turbos in the OEM world more than the tuner scene. However, aftermarket controllers do exist and there’s nothing stopping an intrepid tuners or engine builders from tackling a VGT build. If you need great responsiveness from your turbo engine without compromising on peak power, a variable geometry turbo may be just what you need.

Got a tip? Let the author know: lewin@thedrive.com