The Chrysler Corporation (yes, the car company) used to have an aerospace department. Though it’s clearly not as well-remembered today as its cars, Chrysler did in fact built the predecessors to the Saturn V, the Redstone rockets that sent the Mercury astronauts into space, and—along with Boeing—the Saturn V’s first, largest propulsive stage.

After it had completed all of these amazing projects, the space program started winding down. Cuts under President Richard Nixon meant that there was less money to spend on ambitious projects. Chrysler still wanted a piece of NASA’s budget, though. It was an expert in manufacturing spacecraft and wished to continue doing so. It got its wish when the Shuttle Program came along in 1972.

Chrysler realized that in order to stay in the game, it would have to propose a Shuttle of its own design, competing with other aerospace giants such as Boeing, Grumman, and Lockheed. The result was one of the most unusual looking spacecraft ever proposed. It was also unconventional in its operation, having a single-stage powered by unusual aerospike engines that landed itself ballistically back on earth.

It was called the SERV, and if it was built, it would’ve had SpaceX beat by more than five decades.

Chrysler Goes Nuclear

Chrysler’s involvement with aerospace began when the Cold War started heating up in the early 1950s. The U.S. government was suddenly in need of an ICBM, so the U.S. Army’s Ballistic Missile Agency (ABMA) under the direction of Wernher Von Braun turned to one of its largest manufacturing partners during the war, Chrysler. In no time, Chrysler produced the (mostly German designed) Redstone missile family, the first of its kind in the U.S. These same missiles were converted to carry a passenger for the Mercury program that sent the first American astronauts into space.

Eventually, they would also build the rockets for the Apollo program, culminating in the massive Saturn V in 1961. Although capable of building the entire rocket, Chrysler could not have done it in time, so other manufacturers were subcontracted to build the other stages. They included Boeing, North American, and Douglas.

Then, in 1972, with all of the moon rockets fired off into space, funding for NASA was cut by the Nixon Administration. The public’s enthusiasm for space flight had waned. The budget that remained was only enough for one space-faring venture: the Shuttle Program.

The SERV and MURP

SERV stands for Single-stage Earth-orbital Reusable Vehicle, and it was Chrysler’s booster concept for the Space Shuttle Program. MURP stands for Manned Upper-stage Reusable Payload, which was the cargo and passenger-carrying component of the vehicle. The SERV would get the MURP into space, similar to how the cargo-carrying space shuttle itself rode on the back of a set of powerful rocket boosters.

Although the Detroit automaker delivered the first iteration of its design in November of 1969, the Shuttle story began six years earlier in 1963, when NASA sponsored three studies for reusable spacecraft. A plethora of development work was done by various aerospace companies such as Lockheed, Grumman, and Boeing between 1963 and 1970, putting Chrysler at a disadvantage in terms of development. To make up for this disadvantage, Chrysler’s design was futuristic and unconventional.

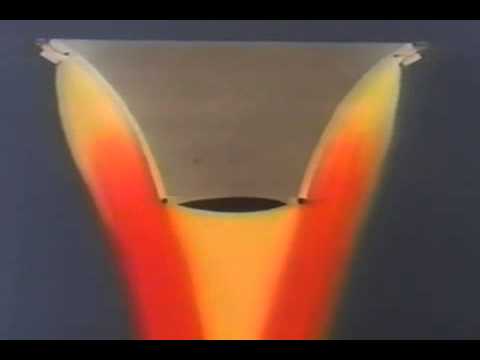

The SERV is an unusual shape for a rocket, looking something like a ballistic acorn. Its unusual shape is the result of a few futuristic features, the first being its aerospike engine.

The aerospike engine isn’t actually a new thing. Rocketdyne had been experimenting with them since the 1960s, and they’re much more efficient than conventional rocket engines. The reason for this is that regular bell-shaped rocket nozzles are optimized for specific altitudes. This may seem like a big drawback, and it is. It’s one of the reasons why conventional rockets like the Saturn V have multiple stages. In a nutshell, an aerospike engine uses the atmosphere itself as a sort of nozzle, allowing for ideal efficiency at any altitude.

The reason they are not in use today is frustratingly simple: the cost. Not the cost of the engines themselves, but the cost of development. As per the video above, NASA and Rocketdyne invested over $500 million for an engine that still wasn’t as proven as conventional bell-nozzled rockets. For reference, the development cost for SpaceX’s entire Falcon 9 launch vehicle—including the engines—was somewhere around $390 million. It’s one of the reasons why Chrysler’s SERV didn’t make it off the drawing board. Its annular aerospike would’ve been expensive and time-consuming to develop, at a time when money was already tight at NASA. It’s the same reason why companies like SpaceX don’t use them today. They are still an unproven and undeveloped technology—as compared to conventional rocket engines, at least.

The other reason for its acorn shape is very relevant today—the SERV was intended to be reusable. The shape is derived from the re-entry capsules utilized by various other space vehicles, including the Saturn V, Mercury, and Soyuz.

You might’ve also noticed on the first drawing provided of the SERV that there’s a square labeled “Turbojet Lift Engines”. These conventional jet engines, 28 of them in all, would’ve been used to slow down the SERV in its final descent, allowing for a soft landing. Jet engines were used instead of rockets to save weight, as jet engines do not require a liquid oxidizer like rocket engines do—just fuel. Plenty of air would be provided for them when they kicked on at 25,000 feet. That was the theory, at least.

The MURP

The Manned Upper-stage Reusable Payload was mounted atop this pudgy rocket and it housed the passengers. Behind it, within the body of the SERV, was a cylindrical cargo bay attached to the back of the MURP. This layout was called the D-10 (a few other layouts were also considered). When the MURP was nearing a space station, it would disconnect from the SERV along with its cylindrical cargo bay, and the SERV would fall back to earth.

The MURP itself was based upon NASA’s HL-10 “lifting body.” I’ll show you a picture of this lifting body in a moment, but it won’t really answer any of your questions when you see it, so I’ll explain it first.

A lifting body is a sort of aircraft with very low drag. It has very low drag because it doesn’t necessarily have wings—the aircraft’s fuselage is shaped to produce lift. Why would you make an aircraft with no wings? Well, it’s because wings, especially non-delta-type wings, produce a lot of drag at high speed. This craft would’ve had to re-enter earth’s atmosphere at tremendous speed, meaning any wings would’ve likely gotten too hot, and failed. But you can’t have a plane without wings, right? Well…

The way they got around it was this: NASA’s HL-10, which was one of several lifting bodies they tested during the 1960s. It was more of a glider than a plane. Of all the designs they considered—one of which they towed around with a hopped-up Pontiac—the HL-10 performed the best, which is why Chrysler chose to design the MURP around it. What a sexy name for what would’ve been one of the fastest vehicles on the planet. Murp.

Just like the Space Shuttle (which is also a lifting body), the MURP would re-enter the earth’s atmosphere and then glide back down to land on a conventional runway. If you’re wondering why the Space Shuttle doesn’t like quite as absurd as the HL-10, it’s because it uses a low-drag delta wing to gain extra lift, which makes it look a little more like a conventional aircraft.

Other Innovations

Chrysler had a variety of other ideas too, some of which are pretty bizarre. Remember, Chrysler was coming into this arena late. It needed to find some kind of edge to get ahead.

According to False Steps, a site about the space race, one of these other ideas was to use the SERV and MURP as a sort of airline operating in low-Earth orbit. Passengers would board the MURP, get shot into space, and land pretty much anywhere else on the planet in 45 minutes. In 1969, they estimated the ticket cost to be between $10,900 and $33,000, or between $76,000 and $230,000 in today’s money.

It’s unclear whether an in-flight meal would be served, which is honestly a deal-breaker for me. I guess I would settle for a hot towel.

They also tried to coax NASA into going with their concept by adding a second, nuclear-powered stage. This stage would be capable of taking cargo or astronauts to the Moon and beyond. How Nuclear-powered rockets work, I’m not sure. I’m not sure Chrysler was entirely certain, either.

Why Did It Fail?

The reasoning behind the government’s decision to cancel any project can be a little murky. It typically has to do with money, but a lot of people think that Boeing’s X-32 (their competitor to the F-35) got canned primarily because it looked weird. That doesn’t seem too unreasonable, honestly.

In this case, it was probably money. The Space Shuttle was considered a reasonably conservative design using a lot of existing technology. Despite this, it had cost overruns north of a billion dollars, and it was late by several years. Chrysler’s more unconventional layout would’ve probably cost even more, and been delayed even longer.

And to be honest, NASA felt as if Chrysler’s spacefaring days were over. They never truly took the company’s entry seriously, even if it did make it through a few phases. More experienced aerospace companies were ready to answer the call.

In the end, Chrysler’s design possibly could have had us leaps and bounds ahead of where we are now, but it’s hard to say for sure. Luckily for us, however, the YouTube channel Hazegrayart created an incredible CGI rendering of what Chrysler’s craft would’ve looked like, and how it would’ve worked.

Got a tip? Send us a note: tips@thedrive.com