We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Complex as airplanes are to develop and to build, they’re even more difficult to improve. Getting flying time for the same or less money is a matter of investing millions to save pennies or seconds, and every aviation player bows to the cause. Case in point: Airbus makes planes, not engines, but it has applied for a patent for a new kind of engine with increased efficiency. The application is for a “Multi-fan engine with an enhanced power transmission,” not only an unwieldy name, but using one version of the setup would result in unwieldy looking planes.

The petition addresses the looming limit of current turbofan development, being that engine makers traditionally get more economical powerplants by installing larger fans at the front – that’s the fan you see when you look at a plane engine, the one that usually has a squiggly line at its center to keep birds away. Airbus says engine makers envision fans 14.5 feet in diameter, but a plane’s wing can only hang so high off the ground; eventually there won’t be enough space to simply put a larger structure underneath it.

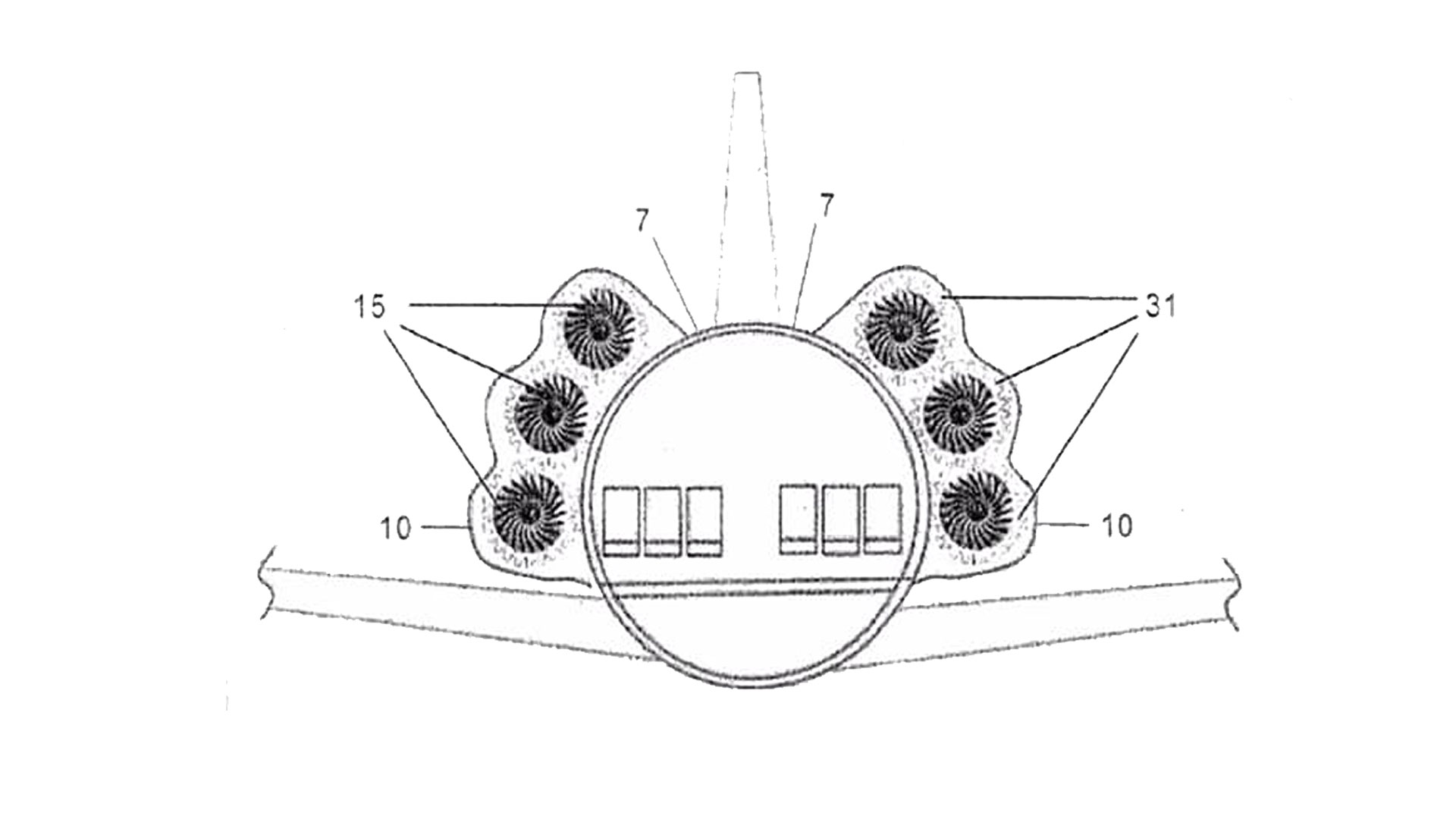

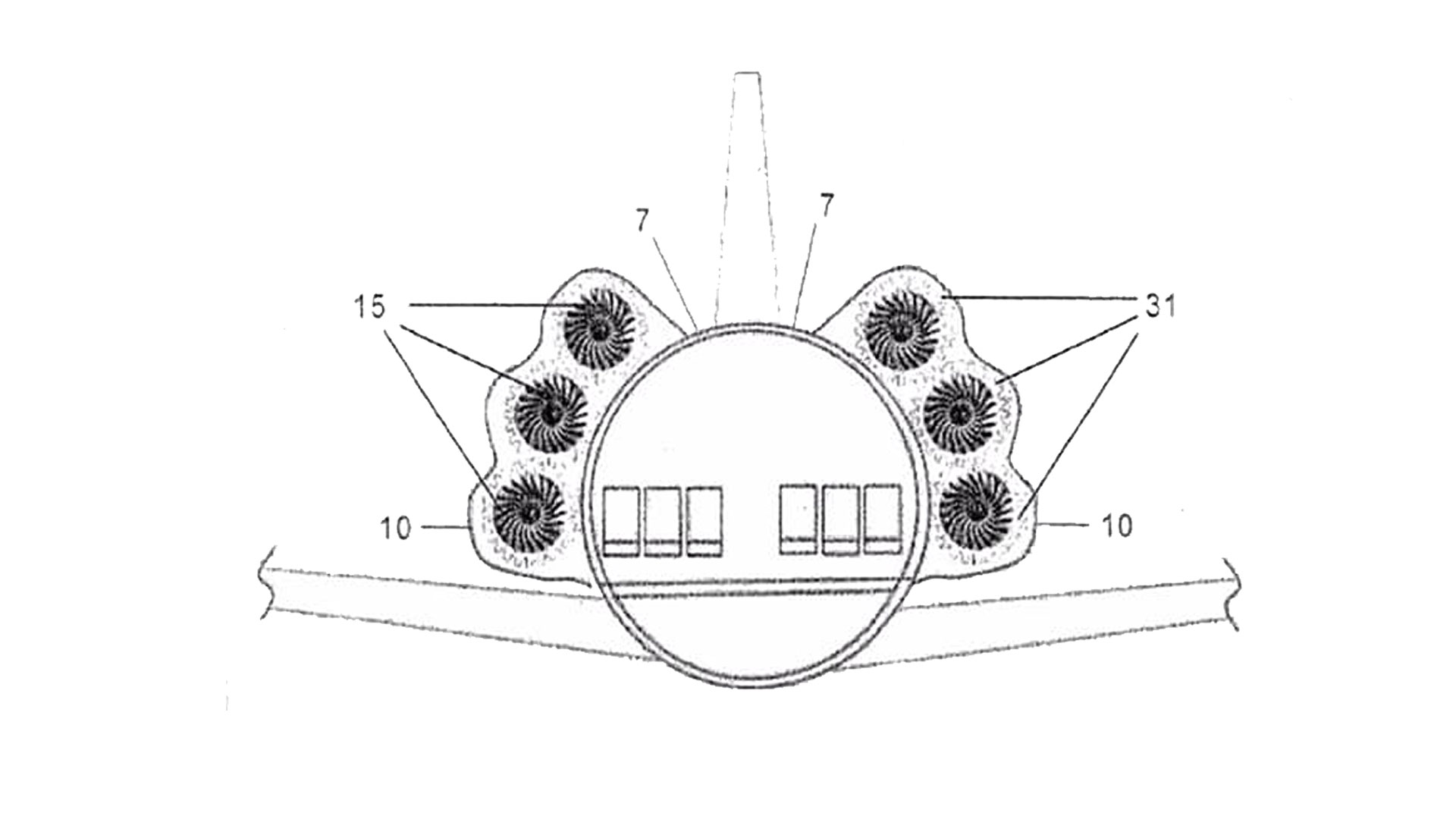

Airbus’ idea is that instead of using one or two large engines with huge fans, use one small engine connected to an array of small fans. This is called a multi-fan engine and it isn’t new – the US Patent and Trademark office awarded a patent to the National Aerospace Laboratory of Japan for the same kind of engine in 2003, did the same for Boeing in 2004, then did the same again for Rolls-Royce (an actual aircraft engine maker) in 2013. In a multi-fan array there’s only one conventional jet-powered engine, with the other fans turned by that one engine via a gearbox or connecting shafts. That gives you the thrust of several fans for fuel costs of just one jet.

Where Airbus diverges from the Boeing and Rolls-Royce designs is how it turns the accessory fans. Instead of a gearbox or linkage, the outside of each fan is fitted with a geared ring. Lined up next to one another, the interconnected gears mean that when the single powered fan turns, you get a counter-rotating array of fans without the complexity of additional shafts or gearboxes. Employing counter-rotation also means less stress on the airframe or wing than co-rotating fans, and potentially more efficiency.

A multi-fan engine can be mounted on the wing, but the patent application suggest that you could get more from the design by placing the design directly on the fuselage. That placement would “capture a significant portion” of the air flowing over the body – called the “boundary layer” – and that could have huge effects on noise, drag, and fuel consumption. It might also be no fun at all sitting next to them.

Plane makers file all kinds of patents that die in obscurity so who knows if we’ll ever see this in action. Frankly, if Airbus were going to fast-track one of its patents we’d rather it were the plane with the removable cabin pod.