During last summer’s run-up to the introduction of NASCAR’s Next Gen Cup Series racer, rumors circulated that the new car wasn’t safe—that it had “killed” a crash test dummy. They followed a June 30 crash test at Talladega Superspeedway, footage of which wasn’t published at the time, fanning the flames of concern among drivers and fans alike. At last, though, the video has been made available, along with information on the car’s crash test performance and what it told NASCAR about how the chassis needed to be changed.

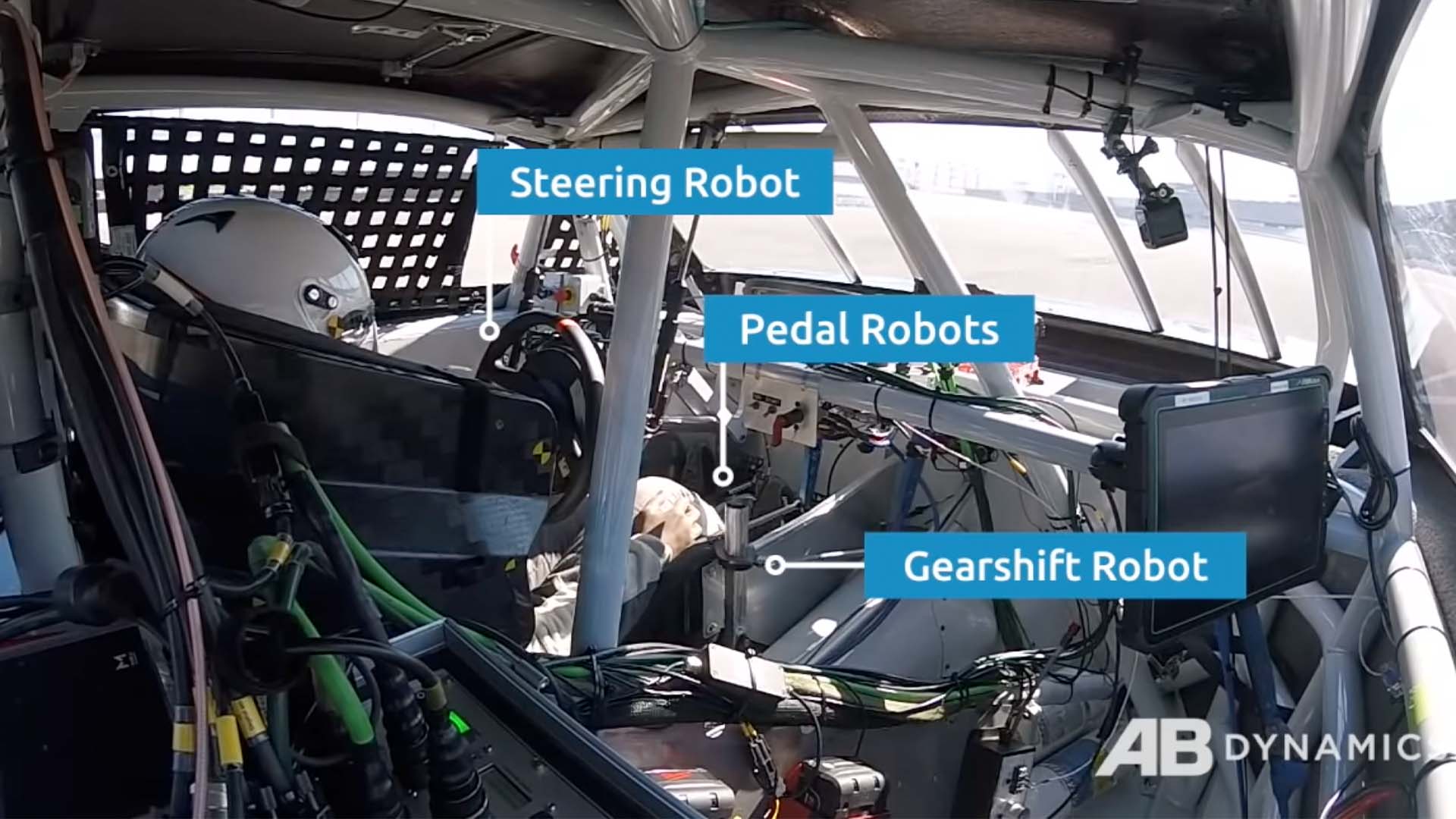

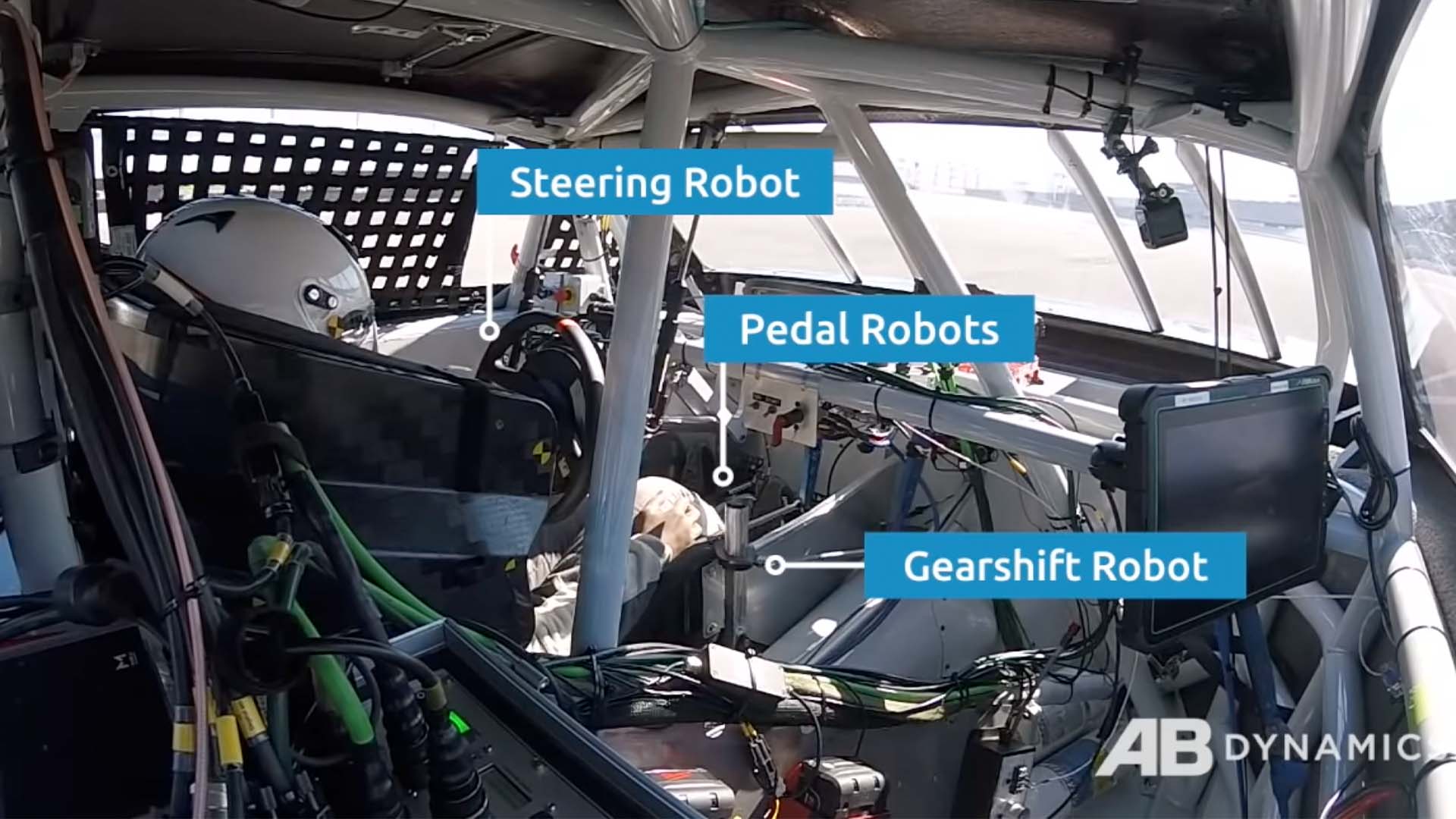

The test itself was an unusual live-fire trial, one wherein a robotically controlled prototype was programmed to crash into the wall at a predetermined location, angle, and speed. The rig, according to PMW Magazine, performed pretty much exactly as intended, colliding with the SAFER barrier at 130 mph and about a 24-degree angle. Footage of the crash confirms that the chassis, rumored to be too stiff, indeed bounced harder off the wall than would be ideal. A NASCAR official, however, told the publication that was expected based on simulations, and that the test gave them what they needed to improve the car’s crash performance.

“The data we obtained from the test was extremely important and was not possible to get from any crash test facilities at the time,” commented NASCAR’s Managing Director for Safety Engineering, John Patalak. “The test provided valuable information for correlation with our computer crash simulations and confirmed that the predicted vehicle impact performance from the simulation was duplicated in this real-world crash test.”

With good data in hand, chassis engineers were able to set about softening the front and rear subframes to improve energy absorption. Major front-end changes were outlined in a Twitter thread by motorsport mechanic Bozi Tatarevic, who pointed out oval cutouts added to the crossbar over the engine bay. This reduced the structural member’s stiffness, allowing more energy absorption, thus decreasing the load on the driver during impacts.

Stewart-Haas Racing’s associate shop foreman Brian Murphy chimed in as well, mentioning notches added near the front clip’s point of attachment to the driver cell. In a large enough crash, those effectively turn the area into a joint, whose deformation expends energy that would otherwise be transmitted to the rest of the frame. Additional changes were also made to the rear of the car based on the test, though specific accounts of what are hard to come by.

This new information on the results of the test should go a long way toward easing fears of drivers’ safety. The drivers themselves have been up to date on the situation for far longer, having been briefed on the true results of the test back in July, and raced the Next Gen car on roughly a dozen occasions this year already. Still, the debacle shows that transparency is always the order of the day when it comes to safety, whether on the track or off it.

Got a tip or question for the author? You can reach them here: james@thedrive.com